The Unseen War: Why Your Trailer Floor is Failing and How to Win

By

Micah Sutfin,

10/24/25

An industrial or trailer floor is not a passive component. It is a high-performance structural asset, engineered to withstand immense stress. Yet, I see them fail constantly. The culprit is rarely a single catastrophic event. Instead, it's a slow, relentless war of attrition waged by an enemy that fleet and plant managers often underestimate: moisture.

The failure of a wood floor in a tractor-trailer or industrial setting isn't a cosmetic problem; it's a critical structural failure that leads to downtime, costly repairs, and significant safety hazards.

To protect your asset, you first must understand the science of the threat.

The Science of a Trailer Floor

Wood is a hygroscopic material. This is a technical term meaning it acts like a sponge, constantly absorbing and releasing moisture to find equilibrium with its environment. This is the root of the problem.

For a trailer floor, this process is on steroids.

- Attack from Below: The undercarriage is perpetually assaulted by road spray, melting snow and ice, and extreme humidity.

- Attack from Above: Wet or frozen cargo, chemical spills, and high-pressure steam cleaning force moisture deep into the wood fibers from the top.

- Extreme Cycling: A trailer can go from a 100°F, high-humidity dock in the South to a sub-zero, dry climate in the North in 24 hours. This rapid cycling of temperature and humidity forces the wood to swell and shrink at a destructive rate.

This constant moisture fluctuation is what destroys the floor. As the wood cells swell with moisture and shrink as they dry, the internal stress causes the wood to check, crack, and warp. In the case of laminated or plywood trailer floors, this stress is the primary driver of delamination—the layers begin to peel apart, and the floor's structural integrity is compromised.

Once a check or crack opens, or the seal is broken by abrasion, water finds a path. This leads to the most catastrophic failure: biological degradation, or rot. The wood fibers are literally eaten away, creating "soft spots" that can collapse under the weight of a forklift, leading to damaged cargo or, worse, a serious injury.

Your First Line of Defense is Not the Wood, It's the Seal

Many assume the wood itself is the only thing that matters. They are wrong. The single most important factor in the longevity of your floor is the quality and durability of its protective seal.

A simple topical finish won't survive. It will be scraped away by the first pallet or worn through by forklift traffic, rendering it useless. You need an engineered solution that does more than just sit on the surface.

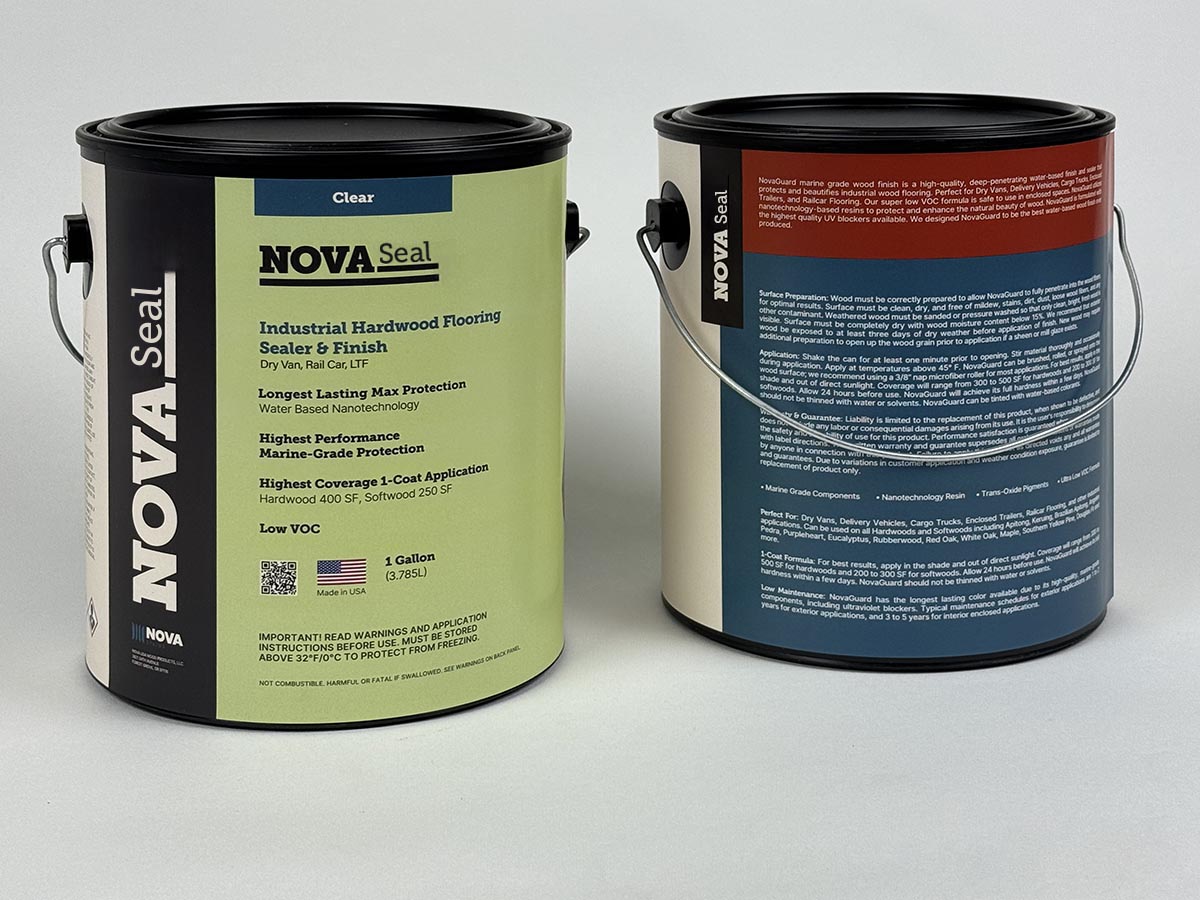

This is where NovaSeal becomes a non-negotiable component of your floor system.

- Deep-Penetrating Encapsulation: NovaSeal is not a paint; it's a penetrating sealer. It dives deep into the wood fibers and encapsulates them, effectively "waterproofing" the wood from the inside out. It creates a robust barrier that drastically slows moisture exchange, preventing the rapid swelling and shrinking that leads to delamination and cracking.

- Safe for Enclosed Spaces (Low-VOC): Formulated with low volatile organic compounds (VOCs), NovaSeal is engineered for safe application in confined areas like the inside of a trailer or container. This powerful penetrating sealer allows crews to work without the hazards of high-odor, high-solvent paints, diving deep to encapsulate wood fibers and block moisture.

- Rapid-Dry Technology for Minimal Downtime: Time is money in any industrial or fleet setting. NovaSeal is engineered with rapid-dry technology, curing quickly to a tough, resilient finish. This drastically reduces vehicle downtime, getting your trailers out of the yard and back into service while still providing superior resistance to forklift and pallet abrasion.

- Locks in Dimensional Stability: By encapsulating the wood and repelling surface moisture, NovaSeal forces the floor into a state of dimensional stability. It minimizes the internal stress, prevents buckling and warping, and most critically, keeps the laminations of a trailer floor firmly bonded.

- Prevents Biological Degradation: This is the bottom line. Rot cannot exist without water. By creating a durable, water-to-repellent seal, Nova Seal denies the conditions necessary for rot and fungal growth.

An Investment in Uptime vs. a Cost of Failure

A failed floor means a trailer is out of service. That is lost revenue, every single day. The cost of replacing a delaminated or rotted trailer floor is astronomical compared to the cost of protecting it correctly from day one.

Treating your industrial and trailer floors with NovaSeal is not a cost; it's a critical investment in your asset's structural integrity and longevity. You are moving beyond simple "wood finishing" and into the science of "wood preservation." You are ensuring your floor can win the relentless war against moisture, keeping your assets in service and on the road where they belong.

Have more questions about NovaSeal and protecting your investment? Visit us at https://www.novausawood.com/nova-seal

By

Micah Sutfin,

10/24/25

Comments?

Display Name:

Contact Email:

please be respectful of others' opinions and do not use profanity.

comments may be edited for objectionable content.

Email addresses are not publicly posted, and are used to follow up directly with your comment as needed.