An industrial or trailer floor is not a passive component. It is a high-performance structural asset, engineered to withstand immense stress. Yet, I see them fail constantly. The culprit is rarely a single catastrophic event. Instead, it's a slow, relentless war of attrition waged by an enemy that fleet and plant managers often underestimate: moisture.

The failure of a wood floor in a tractor-trailer or industrial setting isn't a cosmetic problem; it's a critical structural failure that leads to downtime, costly repairs, and significant safety hazards.

To protect your asset, you first must understand the science of the threat.

The Science of a Trailer Floor

Wood is a hygroscopic material. This is a technical term meaning it acts like a sponge, constantly absorbing and releasing moisture to find equilibrium with its environment. This is the root of the problem.

For a trailer floor, this process is on steroids.

...

Read More -->

By

Micah Sutfin,

10/24/25

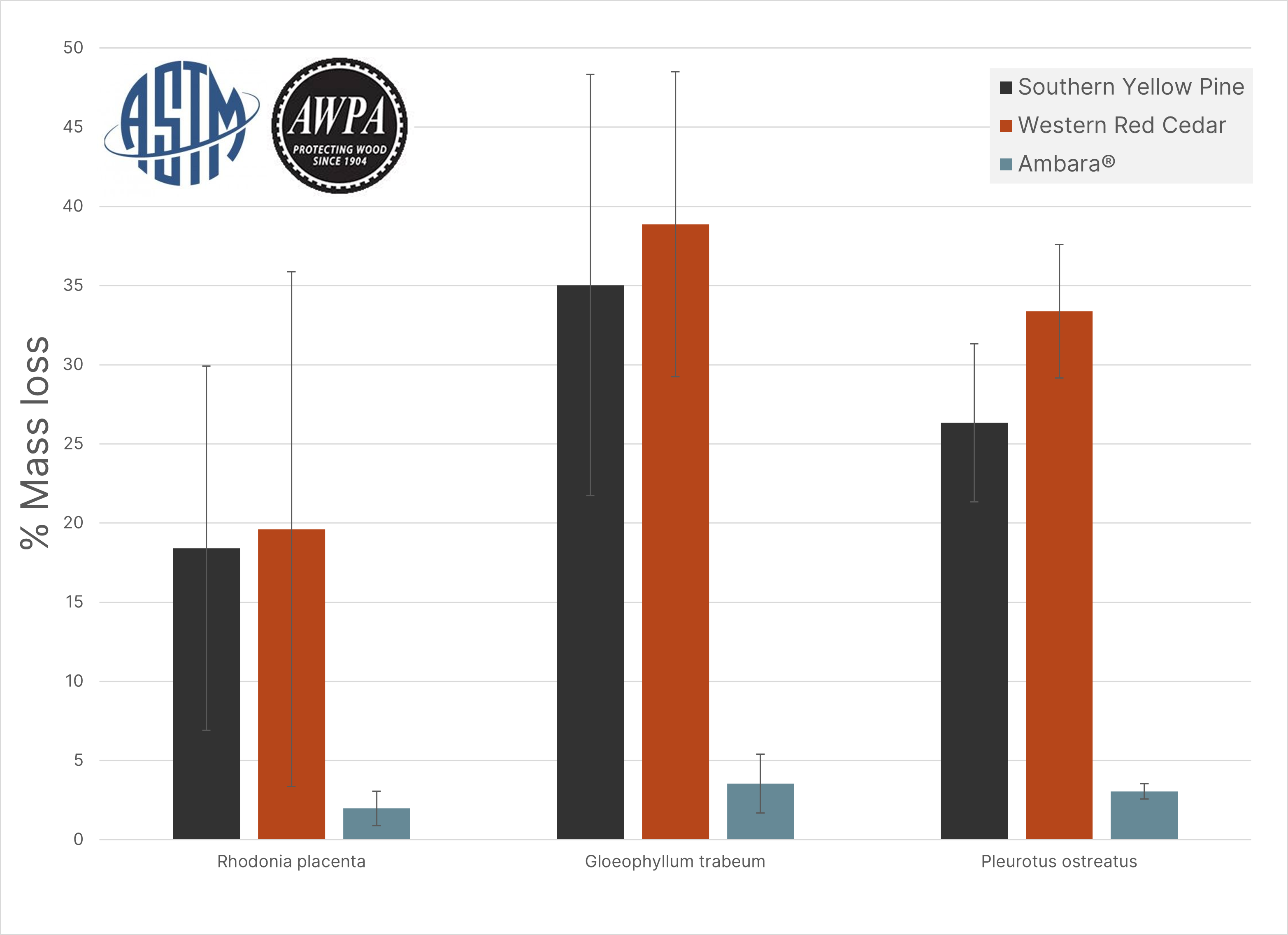

Thermally modified wood siding like Nova's Ambara is an excellent choice for a beautiful, durable, eco-friendly exterior. The thermal modification process uses high heat to change the wood's cellular structure, which removes natural sugars and starches. This makes the wood less appealing as a food source for some insects and gives it enhanced resistance to rot and decay (see figure below).  In other words, thermally modified wood is highly durable against rot and decay, it's not invincible. According to Dr. Jeff Morell from Oregon State University, "All of the evidence we have seen says that thermally modified wood is not resistant to insect attack and, in some cases, appears to be more susceptible due to decreased density." Here are some practical measures to protect your thermally modified wood siding and decking from pests including carpenter bees and termites.

In other words, thermally modified wood is highly durable against rot and decay, it's not invincible. According to Dr. Jeff Morell from Oregon State University, "All of the evidence we have seen says that thermally modified wood is not resistant to insect attack and, in some cases, appears to be more susceptible due to decreased density." Here are some practical measures to protect your thermally modified wood siding and decking from pests including carpenter bees and termites.

PESTS AND PREVENTION

While thermally modified wood resists many common pests, some insects, like carpenter bees and other boring insects, are not attracted to the wood as a food source but rather as a nesting site. While woodpeckers and carpenter bees and termites may still pose a threat, they are often deterred by simple measures.

...

Read More -->

By

Micah Sutfin,

08/27/25

Ipe was listed as CITES Appendix 2 effective November 2024. Volumes in Ipe have been drastically reduced and customers need an alternative hardwood decking choice. Although Ipe is generally still available in limited quantities from many distributors and lumber yards, new shipments from South America have been reduced to around 10% of former imported quantities. Many companies took large positions in anticipation of this projected shortfall. Most major US markets have now run their inventories down to the point where suppliers can no longer meet demand. It's time for alternatives.

Why Hardwood? Biophilic Design Principles.

Natural beauty. Random patterns that don't repeat. The beautiful grain of tropical hardwood. Ribbon sawn, quarter sawn, cathederal patterns... The key difference between man-made materials and natural materials isthe way that it makes you feel when you're hanging out on your deck, in your study, looking up at your wood ceiling, or staring into the depth of a beautiful piece of furniture. It makes you feel relaxed. It's a stress reducer.

First & Second Place - World's Ugliest Deck Contest

Conversely, if you happen to be in a space that has the typical (awful) repeated patterns of wood grain commonly found in PVC / composite decking and fake wood porcelain tile, or fake wood laminates; well, I'm sorry, it's justnot very relaxing, is it? Don't let these ugly products be part of your daily living space.

...

Read More -->

By

Steve Getsiv,

07/16/25

Best Practices For Finishing High Density Hardwood Decks

When it comes to finishing high-density hardwood decks such as Ipe, Torem, Cumaru and Batu application can be a highly arduous task. This is not only because these species have a relatively high density but also because they have smaller vessels than those found in other commercially available hardwoods. While the task of finish application can be difficult, there are solutions for increasing the penetration performance of finishes like Nova's ExoShield™. Enter water popping, a technique commonly used among hardwood flooring installers that promotes the effective and uniform penetration of a given finish. *Note that the water popping method is not intended for film-forming finishes that create a coating or "film" on the wood surface.

What is water popping?

Water popping, also known as grain-popping, involves the application of clean water to an unfinished wooden substrate to open or "pop" high-density wood cells. Wood is inherently hygroscopic, meaning it will readily absorb liquid water. When this occurs, water forces the wood cells to expand. As the water evaporates, the wood's cellular structure will remain open temporarily allowing it to receive finishes more readily.

Finish Penetration

When applying a penetrating oil finish, like Nova's ExoShield™ the product will attempt to absorb into the wood on a cellular level. If the vessels (known as tracheids in softwoods) of a given species are tightly closed the finish will not readily penetrate as desired. This also translates to penetrating oil finishes containing pigments which mitigate UV rays from graying out the wooden surface. Observe the penetration rate of non-water popped vs water popped Torem in the image below hard to believe it's the same board!

...

Read More -->

By

Micah Sutfin,

12/31/24

Background Details

When we bought our house in 2007, there was a newly remodeled outdoor living space which included an upper and lower deck, both with slate tiles and wood burning fireplaces. Initially, we loved these spaces and the lower deck stayed mostly dry. Unfortunately, the construction standards were not all that great and the leaks from the upper deck got to be too much. In 2010, we ended up pulling up all the slate tile on the upper deck and resealing the substrate. We installed a beautiful 1x4 Cumaru hardwood deck which held up great for another 5 years. Then the substrate failed (again) and we pulled the hardwood deck, labeling everything so we could put it all back in the same order. This time we sealed it with a high quality 50 year guaranteed silicon sealer. Unfortunately the damage was already done and the corners of our deck began to settle. Fast forward to 2024 when we finally decided to rebuild the entire structure and do it correctly.

We were really sad to see just how much damage had occurred after only 20 years. Clearly the previous build was not done right. The posts were embedded by about 2" into the glue lam beam.

We had to pull the fireplaces on both levels of the deck. The original deck was built around the fireplace structure which allowed moisture to penetrate at the perimeter.

...

Read More -->

By

Steve Getsiv,

10/31/24